Friday, November 22, 2024

Free Pallet Shed Plans: Build a Strong, Budget-Friendly Shed for Your Yard

Free Pallet Shed Plans: Build a Strong, Budget-Friendly Shed for Your Yard

Tired of overflowing garages and cluttered yards? Yearning for extra storage space without breaking the bank? Then look no further! This guide provides you with free pallet shed plans, empowering you to build a sturdy and stylish storage solution using reclaimed materials. Transform discarded pallets into a functional and attractive addition to your property, all while minimizing environmental impact and maximizing your savings. Get ready to unleash your inner builder!

Assessing Your Needs and Resources

Before diving into construction, carefully consider your specific needs. How much storage space do you require? What dimensions will fit comfortably in your yard? Measure your available space precisely to determine the ideal footprint for your pallet shed. Next, assess your pallet supply. Free pallets are often sourced from businesses like construction sites, grocery stores, and shipping companies. Inspect them carefully; select sturdy, untreated pallets free from significant damage for optimal construction. Remember, you'll need a sufficient quantity to complete the structure, accounting for both the walls and the roof.

Gathering Your Tools and Materials

Beyond the pallets, you'll need several essential tools and materials. This list isn't exhaustive, but it covers the basics: A sturdy saw (circular saw or hand saw), a hammer, screws (various lengths), a drill, measuring tape, a level, protective eyewear, work gloves, and a strong foundation material (concrete blocks or treated lumber are good options). For the roof, consider using inexpensive roofing felt or tar paper for waterproofing and optional shingles for a more finished look. Don't forget about fasteners such as nails or more screws to secure the roofing material. Proper safety gear is crucial throughout the project.

Choosing the Right Pallets

Not all pallets are created equal. Prioritize pallets made from solid wood, avoiding those constructed with weak or damaged components. Check for stamps indicating the type of wood and treatment (heat-treated pallets are safer for outdoor use). Avoid pallets marked with "MB" (methyl bromide), as this fumigant is harmful. Inspect each pallet for loose boards, broken slats, and signs of pest infestation before incorporating it into your shed design. Cleaning the pallets with a wire brush will remove debris and improve their overall appearance.

Step-by-Step Construction Guide

Constructing your pallet shed involves several key steps. First, build a strong base using your chosen foundation material (concrete blocks provide excellent stability). Second, assemble the pallet walls, ensuring alignment and proper spacing. Consider using additional bracing or reinforcement if needed. Next, assemble the roof frame using sturdy lumber, creating a pitched design for optimal water runoff. Then attach the roofing material securely, ensuring proper overlap to prevent leaks. Finally, add a door (consider using a repurposed door or constructing one from additional pallets), and consider adding paint or stain for protection and aesthetic enhancement.

Tips for a Strong and Stable Structure

Here are a few crucial tips for enhancing the structural integrity of your pallet shed:

- Use longer screws for increased strength and durability.

- Reinforce joints using metal brackets or additional bracing.

- Level each component carefully to prevent unevenness and ensure stability.

- Treat the wood with a weatherproofing sealant to protect it from moisture damage.

Finishing Touches and Maintenance

Once your shed is constructed, personalize it! Add a lock to secure your belongings. Consider painting the exterior to enhance its appearance and further protect it from the elements. Regular maintenance will extend your shed's lifespan. Inspect the structure periodically for any signs of damage or wear. Reapply weatherproofing sealant as needed to maintain the integrity of the wood. By following these simple steps, you can enjoy years of reliable storage from your expertly crafted pallet shed.

Thursday, November 21, 2024

Create a Strong Pallet Shed DIY for Your Backyard with These Simple Plans

Build a Strong Pallet Shed: Your Backyard's New Storage Solution

Tired of clutter piling up in your backyard? Dreaming of a neat and organized space to store your gardening tools, outdoor furniture, or seasonal decorations? Then build your own pallet shed! This DIY project is surprisingly achievable, even for novice builders, and offers a fantastic blend of rustic charm and practical storage. This guide will walk you through the process, ensuring you create a robust and long-lasting structure that will enhance your outdoor living area.

Planning Your Pallet Shed

Before you dive into construction, careful planning is crucial. First, determine the size of your shed based on your storage needs and the available space in your backyard. Consider the dimensions of the pallets you'll be using â€" standard pallets are typically 48 inches by 40 inches. Sketch a simple plan outlining the shed’s dimensions, including the door location and any windows you might want to incorporate. Next, secure necessary permits. Check with your local authorities to ensure you meet all building regulations. Finally, gather your materials, which include, reclaimed pallets (inspect them thoroughly for damage), screws, pressure-treated lumber for the foundation and framing (if needed), roofing materials (metal roofing is durable and cost-effective), and any additional hardware like hinges and a door latch.

Building the Foundation and Frame

Creating a Solid Base

Start by preparing the ground. Level the area where your shed will sit, removing any debris or uneven patches. You have several foundation options. A simple and cost-effective choice is a concrete slab, ensuring a level and stable base. Alternatively, you can create a raised foundation using pressure-treated lumber, building a frame that will support the weight of the pallet structure. Ensure the base is large enough to accommodate the overall dimensions of your pallet shed.

Assembling the Pallet Walls

Begin constructing the walls using your reclaimed pallets. Inspect each pallet carefully, ensuring it’s structurally sound and free of loose nails or splinters. You’ll likely need to reinforce some pallets by adding additional screws or bracing. Secure the pallets together using appropriate-length screws, creating a stable and interconnected wall section. Remember to consider the placement of your door and any windows at this stage.

Erecting the Frame and Roofing

Once the walls are assembled, carefully lift them into place on the prepared foundation. Use additional pressure-treated lumber to create a sturdy frame around the perimeter and to support the roof. Ensure the frame is level and plumb to maintain structural integrity. Install your chosen roofing material, securing it firmly to the frame. Metal roofing is a popular choice due to its durability and weather resistance. Remember to add sufficient overhang to protect the walls from rain.

Adding the Finishing Touches

With the basic structure complete, focus on the details. Install a sturdy door, using appropriate hinges and a latch. Consider adding window openings for ventilation and natural light. If desired, paint or stain the pallets to enhance the shed’s aesthetic appeal and protect the wood from the elements. A sealant will further protect the wood from moisture damage. Finally, consider additional features such as shelving units inside the shed to maximize storage space.

Safety First

Throughout the construction process, prioritize safety. Wear appropriate safety gear, including safety glasses, gloves, and work boots. Use caution when working with power tools and always follow manufacturer’s instructions. Ensure all screws are securely fastened and the structure is stable before adding roofing or other heavy components. Regularly inspect your completed shed for any signs of damage or deterioration and address any issues promptly.

Building your own pallet shed is a rewarding experience that combines creativity and practicality. With careful planning and attention to detail, you can create a durable and attractive storage solution that enhances your backyard for years to come. So, gather your tools, and start building!

Build a Pallet Shed for Garden Storage with These Simple Plans

Build Your Dream Pallet Shed: A Simple Guide to Garden Storage Bliss

Hey there, fellow gardening enthusiasts! So, you're looking to build a shed, huh? And not just any shed, a *pallet* shed! Smart move. They're cheap, surprisingly sturdy, and offer a really charming, rustic look. This guide will walk you through building your own pallet shed for garden storage, from start to finish. Don't worry, I'll keep it simple and straightforward â€" even if you're a complete newbie to DIY projects. Let's get started!1. Gathering Your Materials: The Foundation of Your Pallet Shed

Before you even think about hammering a nail, you need to gather your materials. This is the crucial first step, trust me. Rushing this part will only lead to frustration later.A. The Palettes Themselves

The heart and soul of your project! You'll need a good number of pallets, depending on the desired size of your shed. Aim for sturdy, heat-treated pallets (look for the HT stamp). Avoid pallets that look damaged or have significant rot. I recommend getting at least 8-10 standard-sized pallets for a small shed. More is always better if you want a larger space!

Where to find them? Check with local businesses (grocery stores, hardware stores, etc.). Many are happy to give them away for free, just ask nicely! You can also sometimes find them on Craigslist or Facebook Marketplace, though you might have to pay a small fee.

B. Essential Tools

You won't get far without the right tools. Gather these essentials:

- Hammer

- Crowbar or pry bar (for separating pallets if needed)

- Safety glasses

- Work gloves

- Measuring tape

- Level

- Circular saw (or hand saw, but a circular saw will save you a lot of time!)

- Drill with various drill bits

- Screws (exterior-grade, preferably galvanized)

- Nails (if you prefer to use nails instead of screws)

- Post hole digger (if you're building a more permanent structure)

- Concrete mix (if you're setting posts in concrete)

- Optional: Pressure-treated lumber for the base, roof supports and door frame (for extra strength and weather resistance)

C. Optional Extras

These aren't strictly necessary, but they'll make your shed look even better and last longer:

- Wood stain or paint (to protect the wood and add a pop of color)

- Roofing felt or metal roofing

- Hinges for the door

- A latch or lock for security

2. Building the Foundation: The Base of Your Operation

You have two main options for the foundation:

A. Simple Ground Base

This is the quickest and easiest option. Level the ground as best you can, then simply arrange your pallets to create the desired size and shape of your shed. This works best on relatively level ground and for smaller, less permanent sheds.

B. More Permanent Foundation with Posts

For a sturdier, longer-lasting shed, especially if your ground isn't perfectly level, dig post holes in the corners and along the sides (spacing depends on the size of your shed). Set pressure-treated 4x4 posts in the holes, filling them with concrete. Once the concrete sets, you can build your pallet structure on top of the posts. This creates a raised base that's more resistant to moisture and pests.

3. Constructing the Walls and Roof: Bringing Your Vision to Life

Now comes the fun part! Assembling the walls is relatively straightforward. You'll essentially be stacking your pallets. Remember to double-check your measurements to ensure everything lines up properly.

A. Wall Assembly

Begin by securing the pallets together using screws or nails. Work your way up, layer by layer. It's helpful to use a level to make sure your walls are straight and plumb. If you're using pressure-treated lumber for support beams, attach these to the pallets as you build up.

B. Creating the Roof

For the roof, you have several options: A simple lean-to roof is the easiest. For a more complex gabled roof, you’ll need to build a frame using additional lumber. Once the frame is built, you can lay roofing felt or metal roofing on top. This will protect your shed from the elements.

C. Adding a Door

You'll likely need to cut a section out of one of your pallet walls to create the doorway. Use a saw to carefully cut the opening to the desired size. Remember to reinforce the surrounding area with additional wood to prevent structural weakness.

4. Finishing Touches: The Details Matter

Your shed is almost complete! Now's the time to add those finishing touches that will make it really shine:

- Apply a wood stain or paint: This will protect your pallets from the weather and give your shed a more polished look.

- Add hinges and a latch or lock to your door: This will ensure your garden tools and supplies are kept safe and secure.

- Consider adding a floor: This will create a more finished look and make it easier to keep your shed clean.

Frequently Asked Questions

Here are some questions I often get asked about building pallet sheds:

Q: How long does it take to build a pallet shed?

A: The time it takes to build a pallet shed will depend on the size and complexity of the design. A simple small shed could take a weekend, while a larger or more elaborate shed might take several days.

Q: Are pallet sheds weatherproof?

A: Pallet sheds offer some weather resistance, but it's not ideal without extra protection. Applying a wood sealant or using roofing materials significantly improves weather resistance.

Q: Are pallet sheds strong and durable?

A: While pallets aren't as strong as purpose-built lumber, using the right type of pallet (heat-treated) and properly assembling the shed will result in a surprisingly sturdy structure. It's advisable to reinforce the structure if you are planning on storing heavier items.

Q: What if I can't find enough free pallets?

A: You can purchase pallets from online marketplaces or lumber yards. Keep in mind, this will increase the overall cost of your project.

Q: Do I need any permits to build a pallet shed?

A: Permitting requirements vary by location. Check your local building codes and regulations to determine whether or not you need a permit before starting your project.

There you have it! Building a pallet shed is a fun, rewarding project that will add significant value to your garden. Remember to prioritize safety and take your time. Happy building!

Wood Pallet Shed Build: Transform Old Pallets into Your Dream Shed

Wood Pallet Shed Build: Transform Old Pallets into Your Dream Shed

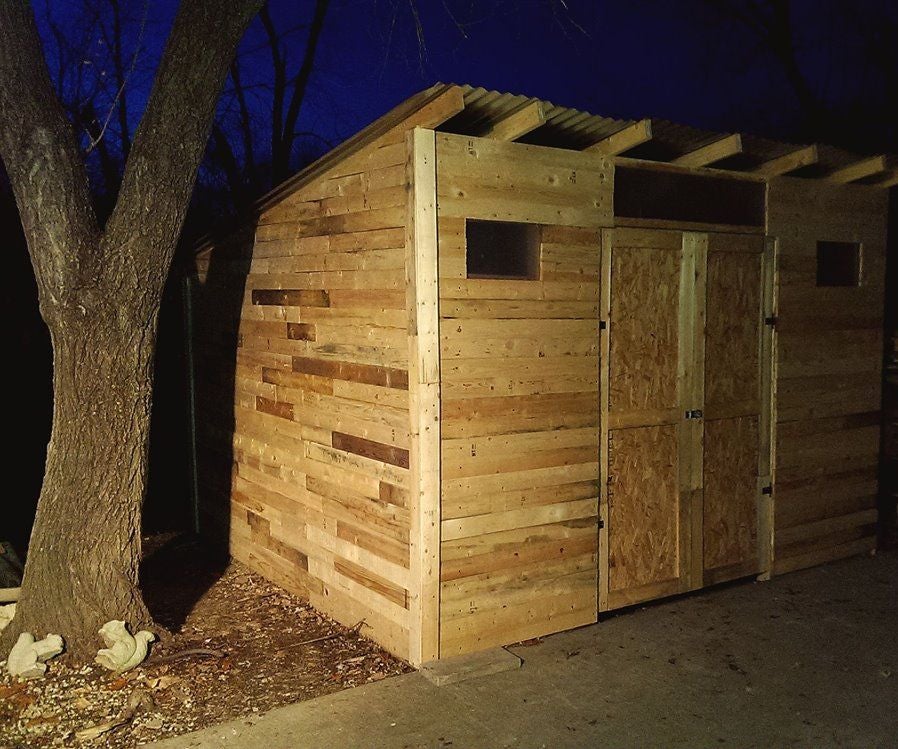

Hey there, fellow DIY enthusiasts! Ever looked at a stack of old wooden pallets and thought, "I could build something amazing with those"? Well, you're in the right place! This guide will walk you through building your own shed using reclaimed pallets, saving you a ton of money and giving you a seriously cool project to brag about. Let's get started on transforming those humble pallets into the dream shed you've always wanted!Planning Your Pallet Shed Project

Before you dive headfirst into hammering and sawing, a bit of planning goes a long way. Seriously, trust me on this one! Rushing into things can lead to frustrating mistakes.Choosing Your Pallets

Not all pallets are created equal. You'll want to source pallets made of strong, sturdy wood â€" preferably heat-treated (look for the HT stamp) rather than chemically treated (MB stamp). Chemically treated pallets might contain pesticides which you wouldn't want near your garden or anything you might store inside.Check the pallets for damage. Broken boards, loose nails, and significant warping are all things to watch out for. You might need more pallets than you initially think to account for unusable ones. Think about the overall aesthetic you want â€" some pallets might be more weathered or stained than others. A little bit of character is nice, but excessive rot is a no-go!

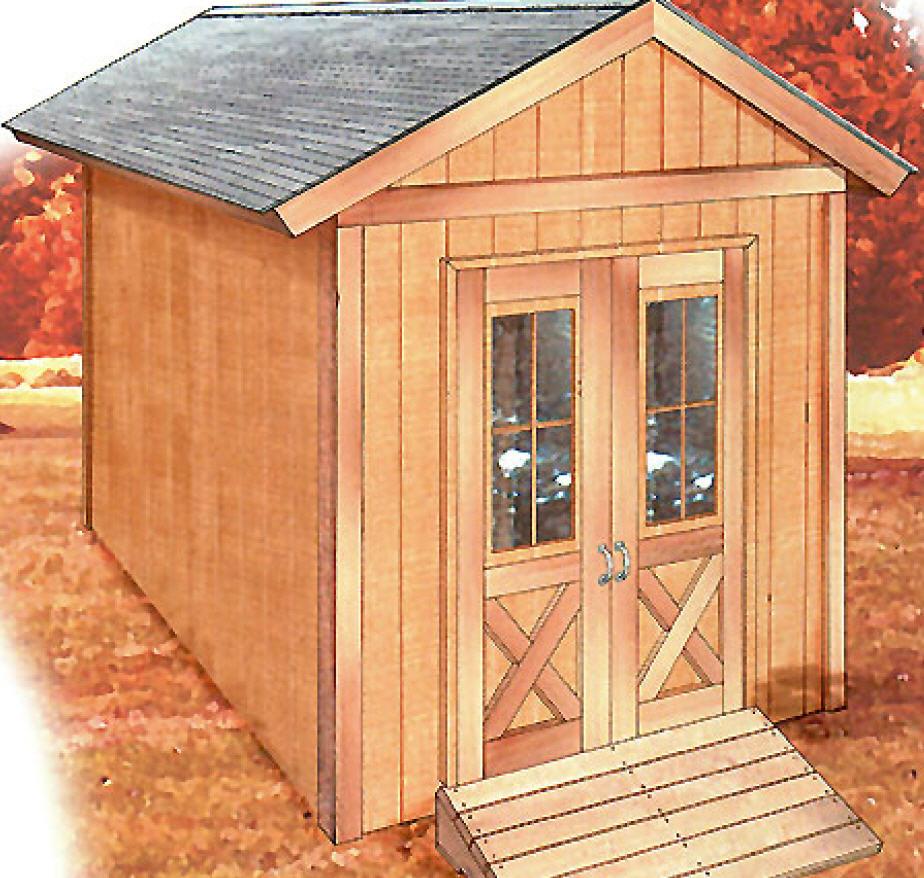

Design and Dimensions

Next up, the fun part: designing your shed! Consider the size you need. How much stuff do you plan to store? A smaller shed is simpler to build, while a larger one requires more materials and expertise. Sketch out a basic plan, noting the dimensions of the walls, roof, and door. You can find free shed plans online for inspiration, just remember to adapt them to your pallet dimensions.Gathering Your Tools and Materials

Now, let's talk tools! You'll need the usual suspects:- Hammer

- Screwdriver (both Phillips and flathead)

- Saw (circular saw or hand saw)

- Measuring tape

- Level

- Drill (with various drill bits)

- Safety glasses

- Work gloves

- Wood screws (various lengths)

- Nails (various lengths)

- Optional: Power nail gun (a significant time saver!)

Beyond tools, you'll probably need additional materials, such as:

- Plywood or OSB (Oriented Strand Board) for flooring and roofing

- Roofing felt or shingles

- Hinges for the door

- A latch or lock for the door

- Treatment for the wood (optional, but highly recommended for longevity)

The Construction Process

Alright, let's get building! This is a general overview, and specifics will depend on your design.Preparing the Pallets

Before you start assembling, you'll need to prepare your pallets. Remove any loose nails or broken boards. If needed, sand down any rough edges to prevent splinters. Consider cleaning the pallets to remove dirt and debris.

Building the Frame

Start by building the frame of your shed using the strongest pallets. This acts as the foundation for your walls. You might need to cut and adjust some pallets to fit perfectly. Use screws to fasten the pallets together â€" they're much stronger than nails in this application.

Adding the Walls

Once the frame is complete, you can begin adding the rest of the pallets to create the walls of your shed. Again, ensure a secure connection using screws or nails.

Constructing the Roof

The roof is often the trickiest part. Depending on your design, you might use additional plywood or OSB sheets to create a stable roof structure before adding roofing felt or shingles.

Adding the Door

Cut an opening for your door and install hinges and a latch. You might need to reinforce the doorway with extra supports. This is an excellent opportunity to demonstrate your creative side!

Finishing Touches

Once the main structure is complete, add a floor (plywood or OSB works well). Apply wood treatment to protect the pallets from the elements, and consider adding a coat of paint or stain to give it a personal touch.

Tips for Success

Here are a few extra pointers to help you along the way:

- Work in a safe environment: Always wear safety glasses and gloves. Make sure the area is well-lit and free of hazards.

- Take breaks: Building a shed is hard work. Don't push yourself too hard. Take breaks to avoid fatigue and injury.

- Ask for help: If you're struggling with a particular step, don't hesitate to ask a friend or family member for assistance.

- Measure twice, cut once: This age-old saying is especially crucial when working with wood.

- Have fun! This is a rewarding project â€" enjoy the process!

Commonly Asked Questions

Q: How long does it take to build a pallet shed?

A: This depends entirely on the size and complexity of your shed, as well as your experience. A small shed could take a weekend, while a larger, more complex one might take several weeks.

Q: How much does it cost to build a pallet shed?

A: The main cost will be for additional materials like plywood, roofing, and fasteners. If you can source pallets for free or very cheaply, the overall cost can be surprisingly low.

Q: Are pallet sheds strong enough?

A: When built correctly using strong pallets and proper construction techniques, a pallet shed can be surprisingly sturdy. The key is to use plenty of screws and ensure the frame is well-supported.

Q: What kind of permits do I need?

A: This depends on your local building codes and regulations. It’s always best to check with your local authorities before starting any construction project.

Q: Can I use treated pallets?

A: It’s generally not recommended to use chemically treated pallets (MB stamp) for a shed, especially if you plan on storing anything that could come into contact with the wood. Heat-treated pallets (HT stamp) are a much safer alternative.

There you have it! Building a shed from reclaimed pallets is a fun, rewarding, and budget-friendly project. So, grab your tools, gather your pallets, and get ready to create your dream shed! Happy building!

Step-by-Step DIY Pallet Shed: Quick and Easy Plans for Beginners

Step-by-Step DIY Pallet Shed: Quick and Easy Plans for Beginners

Constructing a shed can be a daunting task, often requiring extensive carpentry skills and significant financial investment. However, this comprehensive guide offers a simplified approach to building a functional and aesthetically pleasing shed using readily available reclaimed pallets. This project is designed for beginners, emphasizing ease of construction and minimizing the need for specialized tools or advanced techniques. The resulting structure, while not as robust as a professionally built shed, provides ample storage space for garden tools, equipment, or other outdoor necessities.

Phase 1: Planning and Preparation

Before commencing construction, meticulous planning is crucial for a successful outcome. This involves several key steps:

1.1 Site Selection and Assessment

The location of your pallet shed should be carefully considered. Choose a level, well-drained area that receives adequate sunlight but is also sheltered from prevailing winds. Consider proximity to electrical outlets if you plan to utilize power tools within the shed. Measure the intended area to ensure sufficient space for the shed’s footprint, allowing for adequate clearance around all sides for future access.

1.2 Pallet Sourcing and Inspection

Reclaimed pallets are the cornerstone of this project. Source pallets from reputable sources, ensuring they are free from rot, significant damage, or infestation. Inspect each pallet for loose boards, broken slats, or protruding nails. Discard any damaged pallets to ensure structural integrity. Aim for pallets of consistent size and quality for easier construction. You will likely require between 8 to 12 pallets, depending on the desired shed dimensions.

1.3 Material Gathering and Tool Preparation

Beyond the pallets, you will need additional materials. This includes:

- Concrete blocks or a suitable foundation: To raise the shed off the ground and prevent moisture damage.

- Wood screws (various lengths): For secure fastening of pallet components.

- Exterior-grade paint or sealant (optional): To protect the wood from weathering and enhance aesthetics.

- Roofing material (e.g., corrugated metal, plywood): To provide weather protection.

- Hinges and a latch/lock: For the shed door.

Necessary tools include:

- Hammer or mallet: For gently tapping components into place.

- Screwdriver (preferably cordless): For efficient screw driving.

- Measuring tape and level: For accurate measurements and ensuring a level structure.

- Circular saw or hand saw (optional): To cut pallets if necessary. Many pallets are pre-cut to standard sizes.

- Safety glasses and gloves: For personal protection.

Phase 2: Shed Construction

This phase details the assembly of the shed’s structure. Remember to prioritize safety throughout the process.

2.1 Foundation Construction

Create a sturdy foundation by positioning concrete blocks or a similar base in a rectangular pattern, matching the desired footprint of your shed. Ensure the blocks are level using a spirit level. This will provide a stable base and prevent uneven settling of the shed.

2.2 Base Frame Assembly

Using four intact pallets, create a rectangular base frame. Secure the pallets together using wood screws, ensuring strong connections at the corners. Carefully pre-drill pilot holes to prevent the wood from splitting. Check for squareness using a measuring tape or speed square at each corner.

2.3 Wall Construction

Attach additional pallets vertically to form the walls. Interlock the pallets securely by overlapping them slightly. Use screws to connect them to the base frame and to each other, creating a robust and stable structure. For added strength, consider using bracing between pallets to prevent racking.

2.4 Door Construction

Create the shed door using two or three pallets depending on the desired size. These pallets should be carefully attached using screws to form a single unit. Install hinges to attach the door to the assembled frame. Securely install a latch or lock to ensure the shed's contents remain protected.

2.5 Roof Construction

Construct the roof using additional pallets or sheets of plywood. The roof structure should provide sufficient overhang to protect the walls from rain. If using pallets, these can be laid at an angle to create a simple sloped roof. Secure the roof to the top of the walls using screws. For improved weather resistance, consider covering the roof with a suitable roofing material, such as corrugated metal or asphalt shingles.

Phase 3: Finishing Touches

Once the structure is complete, focus on finishing and protection.

3.1 Surface Treatment

Apply an exterior-grade paint or wood sealant to protect the pallets from weathering and enhance their appearance. Allow ample drying time between coats for optimal protection. Consider using a color that complements your existing landscape or garden design.

3.2 Additional Features (Optional)

To further enhance your pallet shed, consider adding features such as:

- Shelving: Constructed from additional pallets or repurposed materials.

- A small window: To improve ventilation and natural light.

- Weather stripping: Around the door for improved insulation and weather protection.

Conclusion

Building a DIY pallet shed is a rewarding project that combines practicality with affordability. By carefully following these steps, beginners can create a functional and attractive storage solution for their outdoor needs. Remember to always prioritize safety and take your time to ensure a sturdy and durable structure. With a little effort and planning, you can enjoy the satisfaction of creating a useful and aesthetically pleasing addition to your property.

Disclaimer: This guide provides general instructions. Always adapt these plans to your specific needs and available materials. Ensure all structural elements are securely fastened and meet local building codes where applicable. Seek professional advice if you have any doubts or concerns regarding structural integrity or safety.

How to Build a Lean-To Shed DIY: Simple Plans for Sustainable Storage

Building Your Own Lean-To Shed: A DIY Guide to Sustainable Storage

Hey there, fellow DIY enthusiasts! So you're thinking about building a lean-to shed? Fantastic! It's a rewarding project that's surprisingly easier than you might think, and the sense of accomplishmentâ€"plus the extra storage spaceâ€"is unbeatable. This guide will walk you through building a lean-to shed, focusing on simple plans and sustainable materials. Let's get started!Planning Your Lean-To Shed: Location, Size, and Materials

Before you even think about grabbing a hammer, some careful planning is crucial. This isn't about stifling your creativity; it's about making sure your shed is both functional and safe.Choosing the Perfect Spot

Think about where your lean-to will be most useful and accessible. Consider:- Proximity to your house: Do you want easy access from the house? Think about the path you'll take with heavy items.

- Sunlight and shade: How much sun exposure do you need or want? Too much sun can damage stored items, while too little might make it damp inside.

- Ground conditions: Is the ground level and stable? You'll need a solid foundation.

- Local regulations: Check with your local council about building permits and setbacks. You might not need one for a small shed, but it’s always best to be sure.

Determining the Right Size

How much storage space do you really need? A smaller lean-to is easier and cheaper to build, but make sure it’s big enough to actually hold your stuff! Measure your potential items, add some extra space for maneuvering, and consider future needs. Remember, you can always add shelving or other organizers inside to maximize space.Sustainable Materials: Choosing Eco-Friendly Options

This is where you can really make a difference! Try to source recycled or reclaimed materials whenever possible. This reduces your environmental footprint and can be surprisingly cost-effective. Consider:- Reclaimed lumber: Look for old barns, demolition sites, or salvage yards. You might find beautiful, character-filled wood at a fraction of the cost of new lumber.

- Sustainable wood: If you're buying new lumber, look for certifications like FSC (Forest Stewardship Council) to ensure it comes from responsibly managed forests.

- Recycled roofing materials: Consider using recycled metal roofing or even repurposed corrugated metal sheets.

- Locally sourced materials: This reduces transportation emissions and supports local businesses. It might even be possible to find someone who will deliver materials free if you don't need immediate delivery.

Building Your Lean-To Shed: A Step-by-Step Guide

Alright, let's get our hands dirty! This is a basic guide; the specifics will vary depending on your design and materials. Always prioritize safety â€" wear safety glasses and appropriate gloves.Foundation: Setting a Solid Base

A simple concrete slab or a compacted gravel base works well for a lean-to shed. For a smaller shed, even a firm level ground can suffice, but for added stability, consider using pressure-treated lumber for the base. Make sure it's level using a spirit level.Framing: The Skeleton of Your Shed

This involves building the frame of your shed using pressure treated lumber. This is where you'll need to use accurate measurements. The frame should be strong and square â€" use a measuring tape, level, and square to check your work frequently. Remember to anchor the bottom frame to your foundation securely.Roofing: Protecting Your Belongings

Your roof design will depend on your overall lean-to design. Simple lean-to roofs are often the easiest to build. You'll need rafters, sheeting, and roofing material. Make sure the roofing material is weatherproof and durable.Walling (If Desired): Adding Extra Protection

If you want enclosed walls, you'll need to construct them after the roof is in place. This usually involves framing and then adding cladding â€" wood siding, corrugated metal, or even recycled pallets could work here!Finishing Touches: Doors and Other Details

Once the structure is complete, you can add a door (if desired), windows for ventilation, and any other features you want.Tips for a Sustainable Build

- Reuse and repurpose: Get creative! Old windows, doors, and even pallets can find new life in your lean-to shed.

- Minimize waste: Cut lumber carefully, and try to use scraps for smaller projects.

- Insulate wisely: Consider adding insulation to the walls and roof to improve energy efficiency (depending on your intended use). Recycled materials can be used for insulation purposes.

- Choose low-impact paints and finishes: Look for natural, non-toxic options to protect your shed and the environment.

- Consider solar lighting: Save on energy and reduce your carbon footprint by using solar-powered lights inside the shed.

Commonly Asked Questions

Q: Do I need a building permit? A: This depends on your local regulations. Check with your local council before starting construction.

Q: How long will it take to build? A: This varies depending on the size and complexity, but a simple lean-to shed can be built in a weekend or two with some help.

Q: What tools do I need? A: You'll need basic carpentry tools like a hammer, saw, measuring tape, level, drill, and screws. Specific tools may vary depending on the materials and design.

Q: Can I build this myself, or do I need professional help? A: With some DIY experience and careful planning, you can absolutely build a lean-to shed yourself. However, if you're not comfortable with construction, it’s always best to get professional help.

Q: How much will it cost? A: The cost varies greatly depending on materials and size. Reclaimed materials can significantly reduce the cost. A simple shed might cost a few hundred dollars, while a more complex one could cost a thousand or more.

Building a lean-to shed is a fantastic way to gain valuable DIY experience, add sustainable storage to your property, and enjoy the satisfaction of a job well done. Happy building!

Step-by-Step Wood Pallet Shed Build: Transform Old Wood into a Sturdy Shed

Step-by-Step Wood Pallet Shed Build: Transform Old Wood into a Sturdy Shed

Hey there, fellow DIY enthusiasts! So you've got a pile of old wood pallets lying around and a yearning for a new shed? Fantastic! You're in the right place. This guide will walk you through building your very own sturdy shed using reclaimed pallet wood â€" saving you money and giving those pallets a new lease on life. Let's get started!Planning Your Pallet Shed: The Foundation of Success

Before you even think about hammering a single nail, let's get the planning sorted. This phase is crucial for a successful build.Choosing the Right Pallets

Not all pallets are created equal. You want pallets that are sturdy, relatively clean, and free from rot or significant damage. Heat-treated pallets (marked with HT) are the safest option, as they haven't been treated with harmful chemicals. Avoid pallets marked with MB (methyl bromide) â€" these are treated with pesticides and should not be used for construction. Inspect each pallet carefully for broken boards, loose nails, and signs of pest infestation.Design and Dimensions

Think about the size and purpose of your shed. Will it house gardening tools, bikes, or something else? This will determine your shed's dimensions. Draw a simple sketch, noting the size of the pallets you have and how you might arrange them. A good starting point for a small shed might be 4ft x 6ft, but you can adjust this to fit your needs and the number of pallets you have. Remember to consider the location of your shed and ensure you have enough space.Gathering Your Tools and Materials

Besides the pallets, you'll need a few essential tools and materials. This list is a good starting point, you might need a few more based on your design:- Hammer

- Pry bar (to remove nails if necessary)

- Saw (circular saw or hand saw)

- Measuring tape

- Level

- Drill and drill bits (for pilot holes)

- Screws (exterior-grade, galvanized are best)

- Nails (optional, for extra reinforcement)

- Safety glasses

- Work gloves

- Post hole digger (if you need to set posts in the ground)

- Concrete (if setting posts in the ground)

- Roofing felt

- Roofing material (corrugated metal, shingles, or reclaimed wood)

Building the Frame: The Bones of Your Shed

Now for the fun part â€" putting it all together! This section details building a simple, rectangular frame. You can always adjust this to create more complex designs.Creating the Base

Start by laying out your pallets on the ground according to your plan. This helps visualize your structure before you start assembling. You can either create a simple base by laying down pallets side-by-side or build a more robust frame with additional lumber for added support. This base is crucial for leveling the structure.Constructing the Walls

Once the base is ready, it's time to build the walls. You might need to cut some pallets to fit or combine sections to achieve the desired height. It’s generally recommended to use strong screws, making pilot holes to prevent splitting. Ensure the walls are plumb and level as you build them, checking frequently with a level.Assembling the Roof Frame

The roof frame will depend on your chosen roofing material. For a simple shed, you can create a gable roof using additional lumber to build the rafters. Make sure the rafters are properly secured to the top of the walls. A simple lean-to shed can eliminate this step.Finishing Touches: Adding the Roof and Refinements

With the basic structure complete, it's time to add the finishing touches.Roofing Your Shed

Install roofing felt to create a waterproof barrier before adding your chosen roofing material. Whether you opt for corrugated metal, shingles, or even more reclaimed wood, make sure it's securely fastened and weatherproof.Adding a Door and Windows (Optional)

Adding a door and windows will depend on your needs and skill level. You can use reclaimed wood or purchase new materials. Make sure any openings are well-secured and weatherproof.Protecting Your Shed

Once your shed is complete, you should protect it from the elements. Applying a wood preservative or sealant can extend the life of your shed considerably.Commonly Asked Questions

Q: How long does it take to build a pallet shed?

A: The time required depends on the size and complexity of your shed. A simple shed can take a weekend, while a more complex project might take several days.

Q: Are pallet sheds durable?

A: With proper construction and maintenance, a pallet shed can be surprisingly durable. Using sturdy pallets and reinforcing the frame is key.

Q: Can I use any type of pallet?

A: No, you should only use heat-treated pallets (HT) for safety reasons. Avoid pallets treated with methyl bromide (MB).

Q: Do I need planning permission?

A: Building regulations vary by location. Check with your local council before starting your project.

Q: What kind of screws should I use?

A: Exterior-grade, galvanized screws are recommended for their durability and resistance to rust.

Q: How do I deal with loose nails in the pallets?

A: Carefully remove any loose nails with a hammer and pry bar. Replace them with screws for a more secure structure.

There you have it! Your very own pallet shed, built from reclaimed materials and a whole lot of DIY spirit. Remember, this is just a guideline; feel free to adapt it to your own creativity and needs. Happy building!Saturday, November 16, 2024

How to Save Money with 12x20 Shed Plans with Loft for DIY Builders

Maximizing Savings: A Comprehensive Guide to Building a Cost-Effective 12x20 Shed with Loft

Constructing a 12x20 shed with a loft offers significant storage solutions, but the project's overall cost can be a deterrent. This comprehensive guide details strategies for DIY builders to minimize expenses while maintaining structural integrity and quality. By meticulously planning and implementing these cost-saving measures, you can significantly reduce the financial burden associated with this rewarding project.

I. Strategic Planning: The Foundation of Cost Savings

Before purchasing any materials or tools, thorough planning is paramount. This phase dictates the overall project cost and efficiency. Failing to adequately plan can lead to costly mistakes, material waste, and delays, ultimately increasing the final expense.

A. Detailed Design and Blueprint Acquisition

While you might be tempted to freehand the design, investing in professionally drawn 12x20 shed plans with a loft is crucial for minimizing errors. These plans provide precise measurements, material lists, and construction details, ensuring accurate material purchasing and preventing costly mistakes during construction. Exploring free online resources or purchasing affordable plans from reputable online retailers can significantly reduce the upfront cost compared to commissioning custom plans. Careful scrutiny of the plans before purchasing is recommended to identify any potential modifications that could impact the overall budget.

B. Material Sourcing and Cost Comparison

Securing materials at competitive prices is a key element in saving money. Avoid impulse purchases. Instead, dedicate time to comparing prices from different suppliers, including local lumber yards, big-box retailers, and online vendors. Consider purchasing materials in bulk to potentially secure discounts. Always verify material quality and ensure that it meets the specifications outlined in your chosen plans. Prioritizing locally sourced materials can reduce transportation costs, further adding to your savings.

C. Tool Inventory and Rental Considerations

Assess your existing tool inventory. Determine which tools you already own and which ones you'll need to rent or purchase. Renting specialized tools, such as post hole diggers or a cement mixer, for tasks requiring only short-term use is significantly more economical than purchasing them outright. Borrowing tools from friends or family can also help reduce expenses. A well-organized tool checklist based on your chosen plans will aid in this assessment.

II. Material Selection and Cost-Effective Alternatives

Smart material selection can greatly impact the project's overall cost without compromising structural integrity. Exploring budget-friendly alternatives while maintaining quality is key.

A. Lumber Selection: Balancing Cost and Durability

Pressure-treated lumber is essential for ground contact, but consider using less expensive lumber for framing elements that are not directly exposed to the elements. Recycled lumber is an environmentally friendly and cost-effective option, provided its structural integrity is verified. Opting for standard dimensions (2x4s, 2x6s) rather than custom-sized lumber minimizes waste and cost. Efficient cutting and minimizing waste during construction further reduces material expenses.

B. Roofing Material Optimization

The roof is a significant cost component. Exploring cost-effective roofing materials, such as metal roofing or composite shingles, provides excellent durability and longevity while often proving less expensive than traditional asphalt shingles. Careful measurement and efficient cutting of roofing materials are crucial to minimizing waste and cost.

C. Siding Alternatives: Balancing Aesthetics and Budget

While vinyl or wood siding offers appealing aesthetics, exploring more affordable options like corrugated metal or composite siding can significantly reduce costs. Consider the long-term maintenance costs associated with each material; a slightly higher initial investment might offset higher maintenance costs in the long run. Painting or staining the shed yourself can further cut down on labor expenses compared to hiring a professional.

III. Labor Optimization: DIY Strategies for Cost Reduction

One of the most significant cost-saving measures is leveraging your own labor. While this demands time and effort, it eliminates the substantial expenses associated with hiring professional contractors.

A. Phased Construction and Skill Assessment

Break down the project into manageable phases, starting with the foundation and progressing systematically. This approach allows for better time management and avoids overwhelming yourself. Honestly assess your skills and experience; don’t hesitate to seek assistance or guidance from experienced DIYers for complex tasks to avoid potentially costly mistakes. Understanding your limitations prevents costly rework.

B. Efficient Work Practices and Waste Management

Efficient work practices, such as precise cutting, careful material handling, and organized storage, minimize waste and speed up the construction process. Proper planning prevents errors, reducing the need for material replacement and rework. Implement a robust waste management plan from the outset. Recycling or repurposing salvaged materials can significantly reduce overall waste.

C. Enlisting Help (Strategically)

While performing most of the work yourself is crucial for cost-saving, enlisting help for physically demanding tasks, such as lifting heavy materials or pouring concrete, can be beneficial. Negotiating assistance with friends or family in exchange for meals or other forms of compensation can be a cost-effective solution compared to hiring additional labor.

IV. Post-Construction Cost Considerations

Even after construction, cost management continues. Addressing these factors post-completion enhances the longevity of your shed and safeguards your investment.

A. Protective Finishes and Maintenance

Applying protective finishes, such as paint or sealant, is crucial for extending the life of the shed’s materials. This helps prevent premature deterioration, reducing long-term repair or replacement costs. Establishing a regular maintenance schedule for inspections and minor repairs further helps protect your investment.

B. Security Measures

Implementing appropriate security measures, such as a sturdy lock, motion-sensing lights, or even a simple alarm system, can help safeguard your valuable stored goods from theft. The cost of these preventative measures is far less than dealing with the consequences of theft or vandalism.

By diligently following these strategies, DIY builders can construct a 12x20 shed with a loft at a significantly reduced cost compared to hiring professionals. Remember that meticulous planning, efficient resource management, and leveraging your own labor are the cornerstones of cost-effective construction. This approach allows you to reap the rewards of a successful project while staying within your budget.

Monday, November 11, 2024

How to Make a Pole Barn with a Traditional Design and Modern Function

The pole barn, a stalwart of rural landscapes, has long been a symbol of practicality and durability. Its simple, sturdy design, often adorned with the charm of weathered wood and rustic accents, evokes a sense of heritage and functionality. Yet, in today's world, where form follows function and modern needs dictate design, it's possible to blend the traditional essence of the pole barn with contemporary elements, creating a structure that is both visually pleasing and highly functional.

Embracing the Classic Elements:

The foundation of a successful pole barn design lies in understanding and celebrating its traditional attributes. These include:

Open Floor Plan: The signature open space within a pole barn, unhindered by interior walls, provides flexibility for various uses, whether it's a workshop, storage space, or even a living area. This open layout creates a sense of spaciousness and allows for adaptability over time.

Post-and-Beam Construction: The defining feature of a pole barn is its robust post-and-beam framework. These large, visible timbers, often made from durable hardwoods like oak or pine, convey strength and stability, contributing to the building's rustic appeal.

Simple Rooflines: Typically featuring a gable roof or a shed roof, pole barns prioritize functionality over intricate designs. This simplicity allows for easy drainage and minimizes material waste.

Natural Ventilation: Pole barns traditionally rely on open vents and doors for air circulation. This natural ventilation promotes a healthy indoor environment, particularly beneficial for workshops or storage spaces.

Incorporating Modern Functionalities:

While respecting the traditional elements, modern pole barns can incorporate features that enhance functionality and aesthetics:

High-Efficiency Insulation: To counter the inherent openness of a pole barn and create a comfortable indoor environment, consider using high-performance insulation within the walls and roof. Modern insulation technologies like spray foam or blown-in cellulose offer excellent thermal resistance while minimizing drafts.

Energy-Efficient Windows and Doors: Strategically placed windows and doors can flood the space with natural light, minimizing the need for artificial lighting. Consider using energy-efficient glazing and framing to reduce heat loss in colder climates.

Advanced Roofing Materials: Beyond traditional metal roofing, modern options like standing seam metal roofs offer increased durability, water resistance, and aesthetic appeal. They can be customized with various colors and finishes to complement the chosen style.

Modern Electrical and Plumbing Systems: To accommodate modern lifestyles, ensure the pole barn is equipped with a well-designed electrical system, including sufficient outlets, lighting, and potentially even a sub-panel for specific appliances. If needed, incorporate a plumbing system for sinks, restrooms, or even a small kitchen.

Interior Finishing Touches: Modern pole barns can utilize a range of interior finishes to create specific ambiance and functionality. While exposed beams and rustic wood accents retain the traditional charm, they can be combined with polished concrete floors, painted walls, and modern fixtures to achieve a contemporary aesthetic.

Bridging the Gap:

The key to achieving a successful balance between traditional charm and modern functionality lies in thoughtful design choices:

Exterior Cladding: Embrace the classic wood siding while exploring modern finishes. Opt for reclaimed wood, weathered barn board, or even a combination of wood and metal panels to achieve a rustic yet contemporary look.

Roofline Features: While keeping the roofline simple, consider incorporating dormers, overhangs, or strategically placed windows to add visual interest and provide additional light and ventilation.

Lighting: Use a combination of natural light and strategically placed LED fixtures to illuminate the space effectively. Exposed Edison bulbs, lanterns, or modern track lighting can all add character and functionality.

Color Palette: The color scheme plays a crucial role in setting the overall tone. Embrace warm, earthy tones like browns, greens, and blues, while using accents of bold, modern colors to add pops of visual interest.

Landscaping: The surrounding landscape can complement the barn's design. Consider incorporating native plants, water features, or even a small garden to create a harmonious and welcoming environment.

Beyond Aesthetics:

The modern pole barn offers a wealth of opportunities beyond aesthetics:

Sustainable Building Practices: Choose locally sourced materials whenever possible, prioritize recycled or repurposed elements, and minimize waste during construction to create an environmentally conscious building.

Multi-Functionality: A modern pole barn can be adapted to suit a variety of uses, serving as a workshop, garage, guest house, home office, or even an event space. Its versatility makes it an ideal investment for various lifestyles.

Increased Resale Value: A well-designed and functional pole barn can significantly increase the value of a property. The combination of rustic charm and modern amenities creates a highly desirable and unique structure.

In Conclusion:

Building a pole barn with a traditional design and modern function is about honoring the past while embracing the present. By understanding the core principles of the pole barn aesthetic and integrating them with modern design elements, you can create a structure that is both aesthetically pleasing and practical, offering a unique blend of heritage and contemporary living.

How to Design a Pole Barn with a Natural Wood Aesthetic

Pole barns, with their straightforward construction and adaptable design, have long been a favorite choice for homeowners seeking functional and durable structures. But beyond practicality, pole barns offer a unique opportunity to embrace the beauty of natural materials, crafting spaces that resonate with warmth and rustic charm. Designing a pole barn with a natural wood aesthetic requires a meticulous approach, blending structural integrity with the elegance of unadulterated wood.

Foundation and Framing: The Essence of Strength and Simplicity

The foundation of a natural wood pole barn lies in its sturdy, exposed posts. Choosing the right timber is paramount. Reclaimed timbers, with their rich patina and history, impart a timeless elegance. Alternatively, new timbers like Douglas fir, cedar, or pine offer durability and a natural beauty that can be enhanced with oil finishes. The posts should be carefully chosen for their straightness and uniformity, creating a foundation of architectural grace.

The roof trusses, ideally constructed from exposed timber beams, become an integral part of the aesthetic. Consider using heavy timber trusses, showcasing the grain and knots of the wood. They offer a sense of rustic grandeur, adding a captivating element to the overall design.

Walls: Embracing the Natural Texture

The walls of a pole barn present a canvas for showcasing the beauty of wood. Several options exist:

Traditional Siding: Vertical or horizontal wood siding, whether rough-sawn or smooth-planed, provides a classic rustic look. Choose a natural wood stain or paint to accentuate the grain and texture.

Shiplap Siding: Shiplap offers a timeless and visually appealing aesthetic, with its overlapping boards creating a textured and inviting surface.

Board and Batten: This traditional siding method utilizes vertical boards with narrow battens covering the gaps, creating a distinctive and elegant look.

Roof: A Capstone of Natural Elegance

The roof, a defining feature of any pole barn, provides an opportunity to accentuate the natural wood theme. A standing seam metal roof, in a dark color that complements the wood, offers durability and a sleek modern aesthetic. Alternatively, a traditional wood shingle roof, with its inherent rustic charm, offers a more traditional look.

Windows and Doors: Framing Views and Welcoming Entrances

Windows and doors are critical design elements, framing views and welcoming guests. Large windows, ideally with a rustic charm, allow ample natural light to flood the interior. Consider using salvaged windows with panes of frosted or patterned glass for a unique and vintage touch.

Doors, crafted from solid wood with simple hardware, should complement the overall rustic theme. A double Dutch door, with its charming design and practicality, adds a touch of elegance.

Interior Design: Embracing Rustic Charm

The interior of a natural wood pole barn should be a reflection of the rustic aesthetic established on the exterior.

Flooring: Hardwood flooring, especially reclaimed barn wood or wide-plank oak, provides a warm and inviting surface. Concrete floors, stained with natural tones, can add a modern industrial touch.

Walls: Exposed beams and wood walls, finished with a natural wood stain or clear coat, create a welcoming and inviting atmosphere.

Lighting: Natural light should be maximized, but strategically placed pendant lights or wall sconces, crafted from reclaimed wood or metal, can add a touch of rustic charm.

Furniture: Choose rustic furniture made from reclaimed wood, handcrafted leather, or metal with a weathered patina.

Sustainability: A Commitment to Nature

A key principle in designing a natural wood pole barn is incorporating sustainable practices. Choose locally sourced lumber, minimizing the environmental impact of transportation. Explore using reclaimed wood, giving old timbers a second life and reducing waste.

The Art of Finishing Touches: Enhancing the Natural Beauty

The finishing touches are crucial in creating a cohesive and elegant design.

Natural Wood Stains: Use stains that enhance the natural beauty of the wood, highlighting the grain and knots.

Weathering and Patina: Allowing wood to age naturally, developing a soft patina, adds character and depth to the design.

Hardware: Choose simple, rustic hardware that complements the natural wood aesthetic.

Conclusion: A Haven of Natural Beauty

Designing a pole barn with a natural wood aesthetic is more than simply choosing materials. It's about embracing the inherent beauty of nature and crafting a space that is both functional and visually captivating. By carefully selecting materials, embracing sustainable practices, and adding thoughtful design touches, a pole barn can become a haven of rustic charm, a testament to the enduring beauty of nature and the art of traditional craftsmanship.

How to Build a Pole Barn with Sliding Doors for Easy Access

The pole barn, with its distinctive simplicity and robust construction, has long been a favorite for a wide range of applications, from workshops and storage facilities to agricultural buildings and even residences. One of the key features that enhances the practicality and accessibility of a pole barn is the inclusion of sliding doors. These doors offer a number of advantages, from ease of operation and space-saving design to improved airflow and the ability to accommodate large equipment or vehicles. This guide will provide a comprehensive overview of the process of building a pole barn with sliding doors, covering essential aspects from planning and materials to construction and finishing.

I. Planning the Pole Barn

A. Determine Purpose and Dimensions:

Begin by clearly defining the intended purpose of your pole barn. This will dictate the required size, layout, and features. Consider factors such as:

Storage needs: What will be stored inside? Will you need to accommodate vehicles, equipment, or large items?

Work area: Is the barn intended for a workshop, hobby space, or other activities requiring workspace?

Livestock housing: Will you be housing animals, and if so, what kind and how many?

Accessibility: Ensure adequate space for loading and unloading, including vehicle access and maneuverability.

B. Site Selection and Permits:

Choose a suitable location for your pole barn, taking into account factors such as:

Access: Ensure easy access for construction vehicles and future use.

Drainage: Consider the natural drainage patterns and potential for flooding.

Utilities: Proximity to power, water, and other essential utilities.

Zoning regulations: Check local zoning ordinances for building restrictions and permits required.

C. Building Codes and Design:

Consult local building codes and regulations for structural requirements, wind load considerations, and other relevant guidelines. These codes often specify the necessary dimensions, materials, and construction methods for your pole barn. Consider hiring a professional engineer to design the structure, especially in areas with high wind or snow loads.

II. Gathering Materials and Tools:

A. Structural Components:

Posts: Typically made of pressure-treated lumber or steel. Choose appropriate sizes based on the design specifications and anticipated load.

Beams and rafters: These components support the roof and walls. Lumber sizes will depend on the span and load requirements.

Sheathing: Plywood or OSB panels used for walls and roof.

Roofing: Metal roofing is common for pole barns due to its durability and longevity.

Siding: Choose siding material based on aesthetics and desired insulation levels.

Doors: Sliding doors offer flexibility and efficient access. Consider the desired size, material (wood, metal, or vinyl), and opening mechanism (manual or automated).

B. Sliding Door Components:

Door tracks: Aluminum or steel tracks provide support and guidance for the door panels.

Rollers: These ensure smooth and effortless door movement.

Hardware: Handles, locks, and other necessary hardware.

Framing: Additional framing around the door opening may be required depending on the chosen door system.

C. Tools:

Power tools: Saw, drill, nail gun, and other essential tools for cutting and fastening.

Measuring tools: Tape measure, level, and square.

Lifting equipment: Hoist or crane for lifting heavy components.

Safety gear: Gloves, safety glasses, and hard hat.

III. Construction Process:

A. Site Preparation:

Clear the site: Remove existing vegetation and debris.

Level the ground: Create a level foundation for the posts.

Set foundation: Install concrete footings or piers, ensuring they meet building code requirements.

B. Erecting Posts and Framing:

Install posts: Securely anchor the posts in the foundation.

Frame the walls and roof: Construct the framing system using beams and rafters, following design specifications.

Sheath the walls and roof: Attach plywood or OSB panels to the framing.

C. Installing Sliding Doors:

Prepare the door opening: Ensure the opening is square and the framing is solid.

Install tracks: Mount the door tracks securely to the framing.

Hang the doors: Attach the door panels to the rollers and slide them onto the tracks.

Install hardware: Add handles, locks, and any other required hardware.

D. Roofing and Siding:

Install roofing: Attach the chosen roofing material to the roof sheathing.

Install siding: Apply the desired siding material to the walls.

Finishing touches: Install windows, trim, and any other desired features.

IV. Maintaining Your Pole Barn with Sliding Doors:

Regular inspections: Periodically check the door tracks, rollers, and hardware for wear and tear.

Lubrication: Keep the rollers and tracks lubricated to ensure smooth operation.

Cleaning: Clean the doors and tracks regularly to prevent dirt and debris buildup.

Repairs: Address any damage or malfunctions promptly to prevent further problems.

V. Advantages of Sliding Doors for Pole Barns:

Easy Access: Sliding doors offer a convenient and unobstructed entryway for large vehicles, equipment, or bulky items.

Space Saving: They require minimal swing space, maximizing usable interior space.

Improved Airflow: Sliding doors can be partially opened for ventilation, allowing fresh air circulation.

Versatility: They can be customized with various materials, sizes, and opening mechanisms to meet specific needs.

Durability: Sliding doors can withstand harsh weather conditions and frequent use.

VI. Conclusion:

Building a pole barn with sliding doors offers a practical and efficient solution for a wide range of applications. By carefully planning, gathering the necessary materials and tools, and following the construction process outlined in this guide, you can create a durable, accessible, and versatile structure that will serve you well for years to come. Remember to prioritize safety throughout the construction process and to maintain your pole barn with regular inspections and upkeep.

How to Design and Build a Pole Barn for Commercial Use

Pole barns, renowned for their versatility and cost-effectiveness, have become increasingly popular for commercial applications. From workshops and storage facilities to retail spaces and agricultural operations, pole barns offer a robust and adaptable solution for diverse needs. This comprehensive guide outlines the key steps involved in designing and building a pole barn specifically tailored for commercial use, ensuring a successful and functional structure.

1. Planning and Design:

a. Define Project Scope:

- Purpose and Functionality: Clearly define the primary use of the pole barn, including specific activities, storage requirements, and desired layout.

- Size and Dimensions: Determine the overall footprint of the building, considering future expansion needs, equipment, and vehicle access.

- Budget and Timeframe: Establish a realistic budget, factoring in construction costs, permitting fees, and potential contingencies. Set a reasonable timeframe for project completion.

b. Site Assessment:

- Location and Accessibility: Choose a suitable site with proper access for construction and future operations, considering proximity to utilities and transportation.

- Soil Conditions and Load-Bearing Capacity: Conduct a geotechnical investigation to evaluate soil stability and determine necessary foundation design.

- Environmental Considerations: Assess potential environmental impacts, such as drainage, vegetation, and wildlife, and implement mitigation measures if required.

c. Design Elements:

- Framing and Support System: Choose appropriate pole materials, typically treated lumber or steel, based on size, load requirements, and desired aesthetic.

- Roofing and Wall Cladding: Select durable and weather-resistant materials, considering factors like insulation needs, aesthetics, and maintenance requirements.

- Doors and Windows: Design entrances and windows to accommodate equipment, traffic flow, and natural light requirements.

- Utilities and HVAC: Plan for necessary electrical, plumbing, heating, ventilation, and air conditioning systems, considering the specific needs of the intended use.

2. Construction Process:

a. Foundation and Footings:

- Concrete Piers or Footings: Concrete piers provide stable support for the poles, while concrete footings distribute the load over a wider area.

- Frost Depth: Ensure the foundation extends below the frost line to prevent heave and damage during freezing temperatures.

- Drainage and Erosion Control: Implement proper drainage systems to prevent water accumulation around the foundation and erosion of surrounding soil.

b. Pole Erection and Framing:

- Pole Installation: Install poles at designated locations, ensuring they are plumb and level.

- Trusses and Beams: Connect poles with pre-engineered trusses or custom-built beams for roof support.

- Wall and Roof Sheathing: Install sheathing boards over the framing to provide a solid base for cladding.

c. Cladding and Roofing:

- Wall Cladding: Apply chosen cladding materials, including metal siding, wood panels, or composite materials, ensuring proper installation and sealing.

- Roofing System: Install the roof covering, considering factors like slope, snow load, and desired aesthetic, utilizing materials like metal panels, asphalt shingles, or tile.

- Insulation: Install insulation if required, considering both thermal performance and moisture management.

d. Doors, Windows, and Utilities:

- Doors and Windows: Install doors and windows, ensuring proper sizing, functionality, and security measures.

- Utility Connections: Connect electricity, plumbing, gas, and other utilities to the building, adhering to local codes and regulations.

- HVAC System: Install and connect heating, ventilation, and air conditioning systems, ensuring proper sizing and distribution throughout the building.

3. Regulatory Compliance:

- Building Codes: Comply with local and regional building codes, including structural, fire safety, and accessibility standards.

- Permits and Inspections: Secure necessary permits from the relevant authorities, undergo inspections at designated stages of construction, and ensure compliance with all requirements.

- Environmental Regulations: Adhere to environmental regulations regarding land disturbance, waste management, and pollution prevention.

4. Finishing Touches and Customization:

- Interior Finishes: Apply interior finishes, such as drywall, paint, flooring, and lighting, to create a functional and aesthetically pleasing space.

- Storage Solutions: Implement appropriate storage systems, shelving, and racking to optimize space utilization for the intended purpose.

- Security Systems: Install security measures, including alarms, cameras, and access control, to protect the building and its contents.

5. Maintenance and Sustainability:

- Regular Inspections: Conduct regular inspections to identify potential problems, such as structural defects, leaks, or equipment malfunctions.

- Routine Maintenance: Perform routine maintenance tasks, including roof inspections, cleaning gutters, and checking electrical systems.

- Energy Efficiency: Consider energy-efficient building materials, insulation, and lighting to reduce energy consumption and operating costs.

Conclusion:

Designing and building a pole barn for commercial use requires careful planning, attention to detail, and compliance with regulations. This comprehensive guide outlines the critical stages, from initial planning to final finishes, ensuring a successful construction project that meets specific needs and enhances business operations. By following these steps and collaborating with qualified professionals, you can realize the versatility and cost-effectiveness of pole barns for your commercial ventures.

Sunday, November 10, 2024

How to design your 8x12 shed on a tight budget

Alright, so you've decided you need a shed. Maybe you're tired of your garage looking like a disaster zone, or you want a dedicated space for your hobbies, or maybe you just want a little extra storage. Whatever the reason, an 8x12 shed is a great starting point. It's big enough to be useful, but not so big that it'll break the bank (unless you go crazy with the upgrades, that is).

The good news is, building a shed on a tight budget is totally doable! You just need to be smart about your choices and be willing to get your hands dirty.

Step 1: The Foundation - The Groundwork for Your Shed

Let's talk foundations. You have a few options, and the best one for you depends on your soil and budget.

Concrete Slab: This is the most expensive option but also the most durable. It's great for heavier sheds or if you plan on adding electricity or plumbing. If you're building on uneven ground, this is the way to go.

Concrete Piers: This is a good middle ground. You'll need to excavate and pour concrete piers at the corners and along the sides of the shed, and then build a wooden frame on top. This is a good option if you have soil that drains well.

Gravel Pad: This is the cheapest option. You'll need to excavate a level area and then lay down a thick layer of gravel. This works well for sheds that are lighter and won't be used for heavy storage. Just make sure you use landscape fabric to prevent weeds from growing up through the gravel.

Step 2: Framing - The Bones of Your Shed

Now for the fun part - the framing! This is where you can really start to see your shed taking shape.

Choosing Your Lumber: Opt for pressure-treated lumber for the bottom plates and any parts of the framing that will be in contact with the ground. This will help prevent rot. For the rest of the framing, you can use regular pine or fir.

Building the Walls: This is pretty straightforward. You'll use 2x4s to build the walls, using studs spaced 16 inches apart. Make sure you add a double top plate for extra strength.

Building the Roof: There are two basic roof options: gable (a traditional A-frame) and shed (a simple sloped roof). Gable roofs are a bit more complicated to build, but they offer more headroom inside. Shed roofs are simpler and easier to build, but they have less headroom.

Step 3: Siding - The Skin of Your Shed

Once the framing is done, it's time to start thinking about the siding.

Cheap and Cheerful: Vinyl siding is the cheapest and most durable option. It comes in a wide variety of colors and styles, and it's easy to clean.

Rustic Charm: If you want a more rustic look, consider using wood siding like cedar or pine. This will require more maintenance, but it adds a lot of character.

Sustainable Choice: Recycled plastic siding is becoming increasingly popular, and it's a great sustainable option. It's durable, weather-resistant, and comes in a variety of colors.

Step 4: The Roof - Keeping the Elements Out

Now let's talk about the roof.

Shingles: Asphalt shingles are the most popular choice, and they're a good balance of price and performance. You can also get architectural shingles for a more upscale look.

Metal Roofing: If you're in a snowy climate, metal roofing is a great option. It's durable, lightweight, and reflects heat, keeping your shed cooler in the summer.

DIY Flair: If you're feeling adventurous, you could even use salvaged materials like corrugated metal or wood shakes to create a unique roof.

Step 5: Windows and Doors - Letting in the Light (and Keeping Things Out)

Now for the finishing touches - windows and doors.

Window Choices: Simple, small windows are often enough for sheds, but consider adding a larger window if you plan to use the shed for hobbies or a workspace.

Door Decisions: Single doors are the most common, but if you're using the shed for a vehicle or large items, you might need a double door.

Step 6: Interior and Extras - Adding Your Personal Touch

Now that the structure is done, it's time to add your personal touch.

Flooring: Concrete is the most durable option, but you can also use wood or even composite flooring for a more finished look.

Shelving: This is a must-have for any shed. You can build your own shelves, or buy pre-made units.

Electrical: If you plan on using your shed for work or hobbies, it's a good idea to add electricity. You'll need to hire a licensed electrician for this.

Step 7: Painting and Finishing - The Final Touches

Finally, it's time to add the finishing touches - paint and sealant.

Painting: A good coat of paint will protect your shed from the elements and make it look great. Choose a paint that's specifically designed for exterior use.

Sealant: A sealant will help prevent water damage and protect your shed from the weather.

Building Your Dream Shed: A Recap

Building a shed on a tight budget is all about making smart choices. You can save money by using recycled materials, doing the work yourself, and choosing simple designs. But don't forget to factor in the cost of tools and materials, and don't be afraid to ask for help if you need it.

Building a shed is a great way to add value to your property and create a useful space for your needs. You'll be surprised at what you can accomplish with a little bit of effort and a whole lot of creativity!

Saturday, November 9, 2024

Build your dream 12x16 storage shed: a step-by-step diy tutorial

Alright, folks, let's talk sheds! You know that feeling, right? That overflowing garage or basement screaming for some relief? That's where a good ol' storage shed comes in. And guess what? You don't need to shell out a fortune to get one. We're going DIY, building a sweet 12x16 shed that'll be the envy of the neighborhood.

Step 1: Gathering Your Supplies

First things first, let's get that shopping list sorted:

Lumber: You'll need pressure-treated 4x4s for the foundation, 2x4s for the framing, and 2x6s for the floor joists. Don't forget your plywood for the floor and roof sheathing, and siding for the exterior.

Hardware: You'll need lots of screws, nails, joist hangers, roofing nails, and maybe some glue for extra strength.

Roofing: Choose your roofing material - asphalt shingles, metal, or even something fancy like cedar shakes.

Doors and Windows: Go for the standard single door for easy access, and maybe add a window for some light.

Extras: Think about extras like a ramp, a loft, or even electricity if you plan on using your shed for more than just storage.

Step 2: Planning & Preparation

Now, before you get all excited and start swinging that hammer, let's plan things out. First, you'll need a level and clear spot for your shed. I recommend a concrete pad, but gravel or even a compacted dirt base will work if you're on a budget.

Tip: Don't forget to check local building codes - some areas require permits for sheds.

Step 3: Building the Foundation

Alright, this is where things get real. You'll be setting the foundation for your entire shed, so make sure it's solid!

Layout: Use your level and measuring tape to mark out the perimeter of your shed. You want those 4x4s perfectly square, so take your time.

Concrete or Gravel: If you're using concrete, pour it to the level of your foundation posts. If you're going gravel, create a level bed for your posts.

Posts: Set your 4x4 posts into the concrete or gravel, making sure they're plumb (straight up and down). Secure them with concrete mix or stakes until the concrete sets.

Tip: Use a construction level and plumb bob to ensure your posts are perfectly square and level.

Step 4: Framing the Floor

Now it's time to build that solid floor!

Joists: Measure and cut your 2x6 floor joists to fit the width of your shed. Use joist hangers to connect them to the foundation posts.

Spacing: Keep your joists spaced 16 inches apart for maximum support. You can add some extra support beams running the length of your shed for added strength.

Sheathing: Lay your plywood sheathing over the joists, screwing it down securely.

Tip: Make sure to cut your joists and plywood precisely. You want a nice, flat surface for your shed!

Step 5: Erecting the Walls

We're getting close to seeing that shed take shape!

Wall Framing: Cut your 2x4 wall studs to the height of your shed. Space them 16 inches apart, creating a strong and sturdy frame.

Corner Posts: Use double 2x4s for your corner posts for extra support.

Wall Sheathing: Nail your plywood sheathing to the walls, creating a solid base for your siding.

Tip: Remember to leave openings for your doors and windows.

Step 6: Adding the Roof

Ready to top it off? Let's build that roof!