Thursday, November 21, 2024

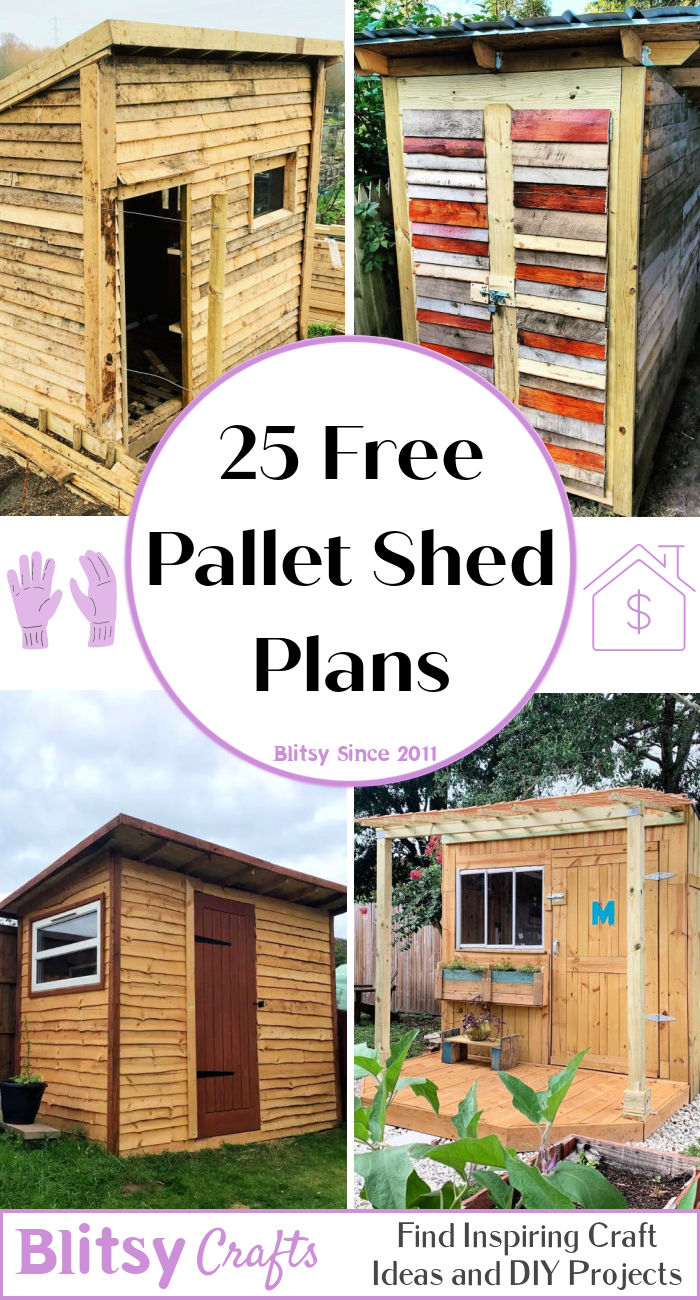

Step-by-Step Wood Pallet Shed Build: Transform Old Wood into a Sturdy Shed

Step-by-Step Wood Pallet Shed Build: Transform Old Wood into a Sturdy Shed

Hey there, fellow DIY enthusiasts! So you've got a pile of old wood pallets lying around and a yearning for a new shed? Fantastic! You're in the right place. This guide will walk you through building your very own sturdy shed using reclaimed pallet wood â€" saving you money and giving those pallets a new lease on life. Let's get started!Planning Your Pallet Shed: The Foundation of Success

Before you even think about hammering a single nail, let's get the planning sorted. This phase is crucial for a successful build.Choosing the Right Pallets

Not all pallets are created equal. You want pallets that are sturdy, relatively clean, and free from rot or significant damage. Heat-treated pallets (marked with HT) are the safest option, as they haven't been treated with harmful chemicals. Avoid pallets marked with MB (methyl bromide) â€" these are treated with pesticides and should not be used for construction. Inspect each pallet carefully for broken boards, loose nails, and signs of pest infestation.Design and Dimensions

Think about the size and purpose of your shed. Will it house gardening tools, bikes, or something else? This will determine your shed's dimensions. Draw a simple sketch, noting the size of the pallets you have and how you might arrange them. A good starting point for a small shed might be 4ft x 6ft, but you can adjust this to fit your needs and the number of pallets you have. Remember to consider the location of your shed and ensure you have enough space.Gathering Your Tools and Materials

Besides the pallets, you'll need a few essential tools and materials. This list is a good starting point, you might need a few more based on your design:- Hammer

- Pry bar (to remove nails if necessary)

- Saw (circular saw or hand saw)

- Measuring tape

- Level

- Drill and drill bits (for pilot holes)

- Screws (exterior-grade, galvanized are best)

- Nails (optional, for extra reinforcement)

- Safety glasses

- Work gloves

- Post hole digger (if you need to set posts in the ground)

- Concrete (if setting posts in the ground)

- Roofing felt

- Roofing material (corrugated metal, shingles, or reclaimed wood)

Building the Frame: The Bones of Your Shed

Now for the fun part â€" putting it all together! This section details building a simple, rectangular frame. You can always adjust this to create more complex designs.Creating the Base

Start by laying out your pallets on the ground according to your plan. This helps visualize your structure before you start assembling. You can either create a simple base by laying down pallets side-by-side or build a more robust frame with additional lumber for added support. This base is crucial for leveling the structure.Constructing the Walls

Once the base is ready, it's time to build the walls. You might need to cut some pallets to fit or combine sections to achieve the desired height. It’s generally recommended to use strong screws, making pilot holes to prevent splitting. Ensure the walls are plumb and level as you build them, checking frequently with a level.Assembling the Roof Frame

The roof frame will depend on your chosen roofing material. For a simple shed, you can create a gable roof using additional lumber to build the rafters. Make sure the rafters are properly secured to the top of the walls. A simple lean-to shed can eliminate this step.Finishing Touches: Adding the Roof and Refinements

With the basic structure complete, it's time to add the finishing touches.Roofing Your Shed

Install roofing felt to create a waterproof barrier before adding your chosen roofing material. Whether you opt for corrugated metal, shingles, or even more reclaimed wood, make sure it's securely fastened and weatherproof.Adding a Door and Windows (Optional)

Adding a door and windows will depend on your needs and skill level. You can use reclaimed wood or purchase new materials. Make sure any openings are well-secured and weatherproof.Protecting Your Shed

Once your shed is complete, you should protect it from the elements. Applying a wood preservative or sealant can extend the life of your shed considerably.Commonly Asked Questions

Q: How long does it take to build a pallet shed?

A: The time required depends on the size and complexity of your shed. A simple shed can take a weekend, while a more complex project might take several days.

Q: Are pallet sheds durable?

A: With proper construction and maintenance, a pallet shed can be surprisingly durable. Using sturdy pallets and reinforcing the frame is key.

Q: Can I use any type of pallet?

A: No, you should only use heat-treated pallets (HT) for safety reasons. Avoid pallets treated with methyl bromide (MB).

Q: Do I need planning permission?

A: Building regulations vary by location. Check with your local council before starting your project.

Q: What kind of screws should I use?

A: Exterior-grade, galvanized screws are recommended for their durability and resistance to rust.

Q: How do I deal with loose nails in the pallets?

A: Carefully remove any loose nails with a hammer and pry bar. Replace them with screws for a more secure structure.

There you have it! Your very own pallet shed, built from reclaimed materials and a whole lot of DIY spirit. Remember, this is just a guideline; feel free to adapt it to your own creativity and needs. Happy building!

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.